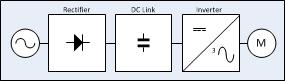

Understanding the basic principles behind VFD operation requires understanding the three basic sections of the VFD: the rectifier, dc bus, and inverter.

The voltage on an alternating current (ac) power supply rises and falls in the pattern of a sine wave

(see Figure 1). When the voltage is positive, current

flows in one direction; when the voltage is negative,

the current flows in the opposite direction. This type

the current flows in the opposite direction. This typeof power system enables large amounts of energy to

be efficiently transmitted over great distances .

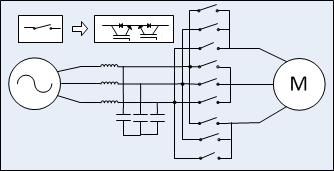

The rectifier in a VFD is used to convert incoming

ac power into direct current (dc) power. One rectifier

will allow power to pass through only when the

voltage is positive. A second rectifier will allow

voltage is positive. A second rectifier will allowpower to pass through only when the voltage is negative.

Two rectifiers are required for each phase of

power. Since most large power supplies are three

phase, there will be a minimum of 6 rectifiers used

(see Figure 2). Appropriately, the term “6 pulse” is

used to describe a drive with 6 rectifiers. A VFD

may have multiple rectifier sections, with 6 rectifiers per section, enabling a VFD to be “12 pulse,”

“18 pulse,” or “24 pulse.” The benefit of “multipulse” VFDs will be described later in the harmonics section.

Rectifiers may utilize diodes, silicon controlled rectifiers (SCR), or transistors to rectify power. Diodes

are the simplest device and allow power to flow any

time voltage is of the proper polarity. Silicon controlled rectifiers include a gate circuit that enables a

microprocessor to control when the power may

begin to flow, making this type of rectifier useful for

solid-state starters as well. Transistors include a gate

circuit that enables a microprocessor to open or

close at any time, making the transistor the most

useful device of the three. A VFD using transistors

in the rectifier section is said to have an “active

front end.”

After the power flows through the rectifiers it is

stored on a dc bus. The dc bus contains capacitors

to accept power from the rectifier, store it, and later

deliver that power through the inverter section. The

deliver that power through the inverter section. Thedc bus may also contain inductors, dc links, chokes,

or similar items that add inductance, thereby

smoothing the incoming power supply to the dc bus.

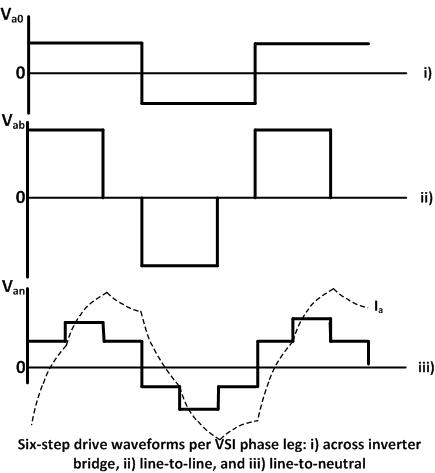

The final section of the VFD is referred to as an

“inverter.” The inverter contains transistors that

deliver power to the motor. The “Insulated Gate

Bipolar Transistor” (IGBT) is a common choice in

modern VFDs. The IGBT can switch on and off several thousand times per second and precisely control

the power delivered to the motor. The IGBT uses a

method named “pulse width modulation” (PWM)

to simulate a current sine wave at the desired frequency to the motor.

Motor speed (rpm) is dependent upon frequency.

Varying the frequency output of the VFD controls

motor speed:

Speed (rpm) = frequency (hertz) x 120 / no. of poles

0 comments:

Post a Comment